Plastica

Description

“Plastica” system is composed of rigid modular elements with a white finish: the elements are made of polypropylene, and the thickness varies according to the diameter. The elements have a male-female "glass slip on coupling" with a triple-lip seal seat. The system is certified to resist to acid condensation, and must be applied in plants (gas or condensing oil) with maximum operating temperature up to 120°C.

Applications

- Flue pipe,

- plastic connecting flue pipe,

- for the evacuation of condensed humid smokes,

- under pressure or depression,

- of condensing generators and/or kitchen hoods

Fuels and product use suitable for

Application of the product

Available diameters

60-80-100 (in stock) 125-160-200 (only on request)Gaskets

Included and installed from D.80 to D.200.Designation of the product

Product marking according to the European rule: CE 0476 EN 14471.

Plastica

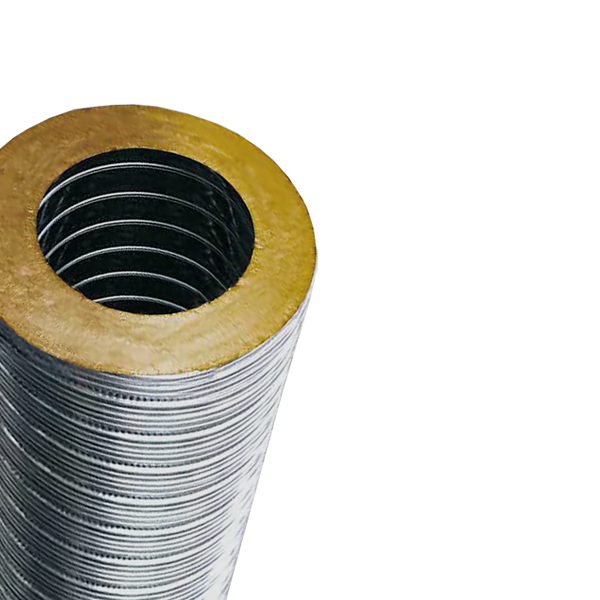

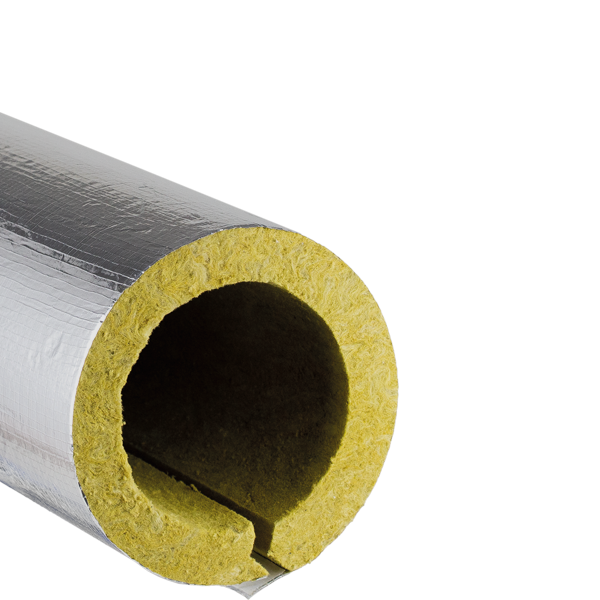

Description of the product

A: PPS white color

B: Thickness: D.60 2mm – D.80 2mm – D.100 2,4mm – D.125 2,7mm – D.160 3,2 – D.200 4,0mm

C: MAX 120°C (Condensation)

D: Silicone EPDM gasket from (-90°C to +200°C)

Use with gasket

EN 14471: T120 – P1 – W – 2 – O00 LI E U

EN 14471: T120 – H1 – W – 2 – O00 LI E U

CHIMNEY SYSTEM EN 1856/1: RULE OF REFERENCE

T120: Class of temperature (120°C)

P1 / H1: Class of pressure (P1: 200Pa)(H1:5000Pa)

W: Resistance and condensation tightness (W: Wet)

2: Resistance to corrosion (Yes)

O: Resistance to fire soot (O: no – G: yes)

(00): Distance from combustible materials (0 mm)

LI: Positioning (only indoor)

E: Reaction to fire (poor flame reaction properties)

U: Protection (no protection)