Mono Eco 50-60-80

Description

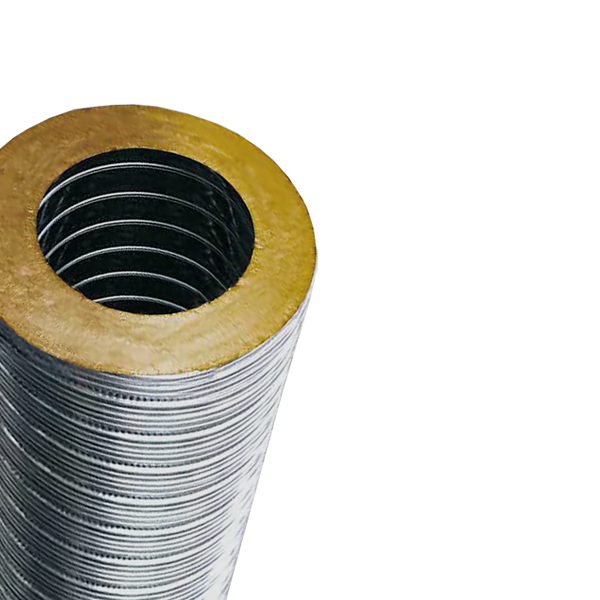

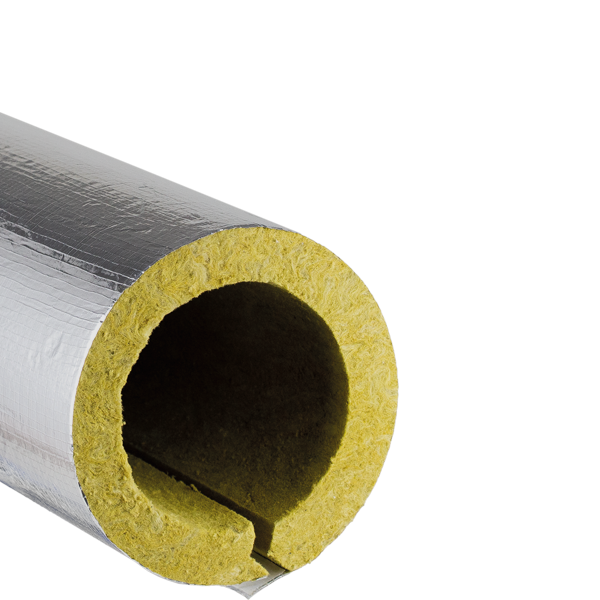

"Mono Eco" system is composed of some rigid modular elements with bright finishing BA for thickness 0,5 mm, finishing 2b for thickness 0,6 mm or BA finishing for thickness 0,8 mm. All items are manufactured in stainless steel AISI 316L (1.4404) for all three categories of thickness. The elements have a male-female "glass slip on coupling" with a triple-lip seal seat. A mechanical seal joint is guaranteed through the use of the locking band.

Applications

- Ducts, connecting flue pipes,

- metal chimneys for the evacuation of dry or wet smokes,

- under pressure or depression,

- from the appliance to the atmosphere,

- or connection from the appliance to the chimney

Fuels and product use suitable for

Application of the product

Available diameters

150 - 160 - 180 - 200 - 230-250 -300 - 350Upon request "big diameter" variation

400 - 450 - 500 - 550 - 650 - 700 -750 - 800 - 850 - 900 (For All Thicknesses )

Gaskets

Included and installed from D.80 to D.150 for thickness 0,5 mm. For all other diameters and thicknesses the gaskets are upon REQUEST.Designation of the product

Product marking according to the European rule: CE 0476 EN 1856-2.

Mono Eco 50-60-80

Description of the product

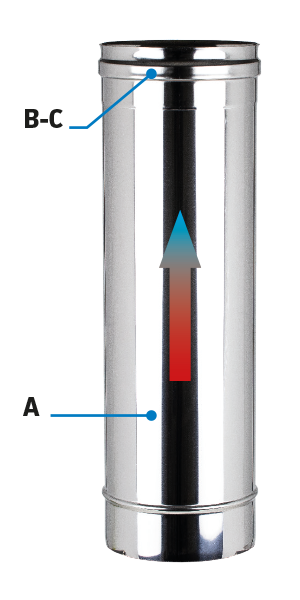

A: Material Stainless steel AISI 316L (1.4404) th. 5/10 – 6/10 – (8/10 upon request)

B: Male-female “glass slip on coupling” with a triple-lip seal seat

C: Silicone gasket from (-90°C to +200°C)

Use with gasket

EN 1856/2 09 : T200 – P1 – W – V2 – L50050 – O (xx) (5/10 thickness)

EN 1856/2 09 : T200 – P1 – W – V2 – L50060 – O (xx) (6/10 thickness)

EN 1856/2 09 : T200 – P1 – W – V2 – L50080 – O (xx) (8/10 thickness)

CHIMNEY SYSTEM EN 1856/2: RULE OF REFERENCE

T200: Class of temperature (200°C)

P1: Class of pressure (P1: 200Pa)

W: Resistance and condensation tightness (W: Wet)

V2: Resistance to corrosion (Yes)

L50: Specification of the material (stainless steel 1.4404 AISI 316L)

050 o 060 o 080: Thickness of the material (050 thickness 5/10) – 060 (thickness 6/10) – 080 (thickness 8/10)

O: Resistance to soot fire (O: no – G: yes)

(xx): Distance from combustible materials in mm

Distance in standard working conditions: (75) : from D.80 to D.300 – (115): from D.301 to D. 450 – (150): from D.451 to D.600 – (300) : bigger than D.600

Use without gasket

EN 1856/2 09 : T600 – N1 – D – V2 – L50050 – G (zz) (5/10 thickness)

EN 1856/2 09 : T600 – N1 – D – V2 – L50060 – G (zz) (6/10 thickness)

EN 1856/2 09 : T600 – N1 – D – V2 – L50080 – G (zz) (8/10 thickness)

CHIMNEY SYSTEM EN 1856/2: RULE OF REFERENCE

T600: Class of temperature (600°C)

N1: Class of pressure (N1: 40Pa)

D: Resistance and condensation tightness (D: Dry)

V2: Resistance to corrosion (Yes)

L50: Specification of the material (stainless steel 1.4404 AISI 316L)

050 o 060 o 080: Thickness of the material (050 thickness 5/10) – 060 (thickness 6/10) – 080 (thickness 8/10)

G: Resistance to soot fire (O: no – G: yes)

(zzM): Distance from combustible materials in mm – M=measured

Distance in conditions of soot fire: (600M): from D.80 to D.300 – (900M): from D.301 to D.450 – (1200M): from D.451 to D.600 – (2400M): bigger than D.600